Preface

Welcome to this guide on Industrial SBS spray adhesives. It is a comprehensive and high-performance bonding solution, which is critical for industrial applications like upholstery manufacturing, mattress production etc. Are you facing challenges with product adhesion and bonding? Well, you have come to the right place.

In this article, we will uncover what makes them so strong. Let us explore the science behind these incredible adhesives, deconstruct their chemical composition, examine their key advantages and disadvantages, and show you their diverse applications.

But our story doesn’t end there. We’ll also give you an exclusive look at the Fokis professional series and our passion for custom formulas. Discover how we work side-by-side with you to build robust, lasting solutions designed to solve your specific challenges.

- What Are SBS Spray Adhesives?

- SBS Spray Adhesives: Advantages vs Disadvantages

- Industrial Applications of SBS Spray Adhesives

- How to Apply SBS Spray Adhesives

- Introducing Fokis’s SBS Spray Adhesives

- Custom SBS Spray Adhesive Solutions

What Are SBS Spray Adhesives?

SBS solvent-based spray adhesive, often known as “oil-based spray adhesive,” is a high-performance and versatile adhesive solution, which is widely used in industrial and construction applications, especially where bonding soft and flexible materials is critical.

So, what makes it so effective? The secret of SBS spray adhesive lies in its unique chemical composition. As a solvent-based system, the core adhesive polymer is suspended in a specialized solvent carrier. When sprayed, this carrier evaporates almost instantly, leaving behind a highly tacky adhesive that creates a powerful, rapid bond.

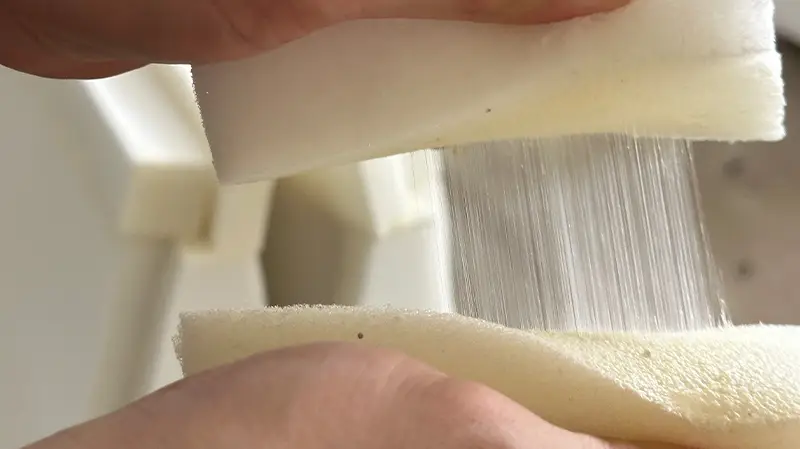

Ever wonder how our adhesive can be both incredibly strong and remarkably flexible? The secret lies in its super DNA: the SBS (Styrene-Butadiene-Styrene) polymer. At a molecular level, it’s a block copolymer engineered with a unique ‘hard-soft’ chain structure.

The “S” (Styrene) segments act as hard, structural anchors. They provide immense cohesion, which is the source of the bond’s strength and durability.

The “B” (Butadiene) segments act as soft, flexible connectors. They impart remarkable, rubber-like elasticity to the adhesive layer.

This brilliant molecular design is the key. After curing, it creates an adhesive layer that is simultaneously strong and flexible. This makes it the perfect solution for bonding soft materials like foam and fabric, ensuring a bond that holds firm without ever becoming brittle.

SBS Spray Adhesives: Advantages vs Disadvantages

Advantages of SBS spray adhesive

- Strong Initial Tack: Provides an immediate, powerful grip upon contact. This significantly reduces clamp time and accelerates your production workflow, boosting overall efficiency.

- Exceptional Flexibility: The bond line remains soft and pliable even after fully curing. This is critical for applications involving foam and fabric, as it preserves the material’s natural feel and prevents stiffness or cracking.

- Controllable opening time: it is controllable according to the requirement of different items application.

- Mature & stable technology: as a classic formulation, ensuring consistent and reliable quality.

Disadvantages of SBS spray adhesive

- Ventilation & Respiratory Protection

- Fire Hazard & Storage: store and use away from all potential ignition sources.

- Material Compatibility: may cause slight corrosion on sensitive plastics, such as polystyrene (PS) foam boards. Please do a pre-test before using it widely.

Industrial Applications of SBS Spray Adhesives

With its excellent overall performance, SBS spray adhesive is the go-to choice for professionals in a wide range of industries, including:

- Soft furniture manufacturing

- Mattress production

- Automotive decoration

- Luggage & handbags

- Office furniture

- Exhibition decoration

How to Apply SBS Spray Adhesives

Application methods for SBS spray adhesive range from manual to automated, depending on adhesive properties and application requirements. Spraying method is the primary application method as it is simple to operate and high-efficient. The detailed steps for the spraying process are as follows:

- Surface preparation: ensure the bonded surfaces are clean, dry, and free of oil and dust.

- Even spraying: using a hand-held spray gun, maintain 15-25 cm from the surface, spray evenly over both surfaces.

- Tack-Up time: wait 1-4 mins until it is tacky but not stringy. The adhesive is ready for bonding when it is aggressively tacky to the touch but does not transfer or create “strings.”

- Bonding and pressing: line up the surfaces and press them together firmly.

- Curing and handling: achieves full strength in 24 hours; avoid stress on the bond during this period.

We can precisely tailor this adhesive’s key properties—including viscosity, open time, and curing speed—to meet your specific production line and application requirements. Contact our technical team to engineer the optimal solution for your process.

Introducing Fokis’s SBS Spray Adhesives

As specialists in the adhesive industry, Fokis understands what challenges our customers face when selecting products. To settle these challenges, Fokis offers a complete range of high-performance spray adhesives.

- Low-VOC series: A new generation of low-VOC, low-odor SBS spray adhesives, which provides a powerful adhesion, reduces odor, and is good for the health of workers.

- Anti-Corrosion series: For sensitive plastics such as polystyrene (PS) foam boards, we have re-engineered and updated the traditional formula to ensure compatibility.

- Water-Based series: More environmentally responsible and safer for health.

Custom SBS Spray Adhesive Solutions

Choosing the right adhesive is just the beginning. Fokis is more than just a developer and supplier of adhesives, we are your bonding technology consultants, providing reliable and effective customized solutions tailored to your specific application.